SECOTA blog

SECOTA (Security, Equivalent, Certification, Organization, Testing and Auditing) is a comparison test project. It is based on the principle that a comparison test shall be open and transparent. In this blog current updates of the SECOTA project are given to the market.Importance of accreditation

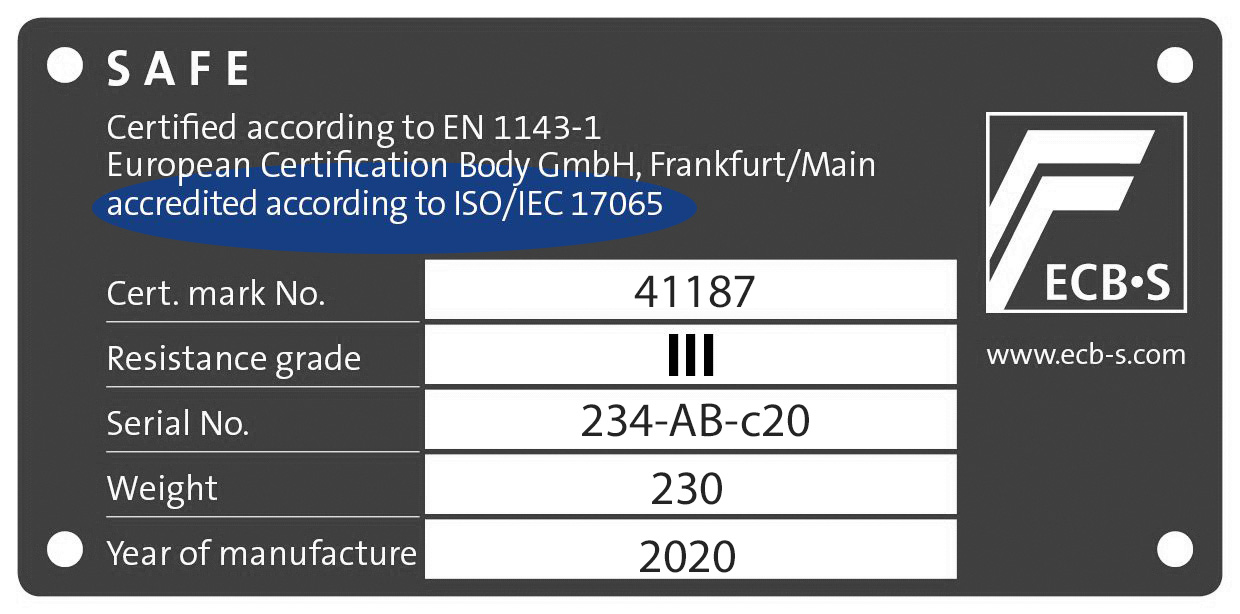

For most security testing requirements "self-declarations" by manufacturers for safes are obviously insufficient. For this reason, security standards which in the past had integrated a manufacturer self-declaration like the VDMA 24992 were withdrawn long ago. The reason for this is simple. A manufacturer will likely be biased towards their own products. Third party assessment by a certification body will of course provide more assurance than "self-declaration" but it is also important to be assured that the certification body itself is independent and has the required competence and facilities to assess the security of a safe in the first place.

|

|

| Without accreditation to ISO/IEC 17065 it is simply impossible to know if a body issuing a certificate for a safe is impartial or even competent. Accredited certification protects the consumer and the insurer of safes from sub-standard units and other nasty surprises such as hazardous materials. As important, is the fact that in a legal sense an accredited certificate has standing as proof of standard for litigation purposes. A case in point is the fact that Governments from several countries are now requiring that safes for the storage of weapons must be shown to have such accredited European certification. | Where it [the certification body] is found to be competent, the national accreditation body shall issue an accreditation certificate to that effect. |

Interim Report on the SECOTA Project

December 2019 - „The first practical test series in international testing laboratories in the course of the SECOTA project has been completed“, reported Falko Adomat, Deputy Managing Director of the European Security Systems Association (ESSA), at the ESSA General Assembly 2019 in Frankfurt. This is the largest independent comparative test in accordance with EN 1143-1 to date, with each laboratory starting with the same requirements. The complete press release is available as download under the following link. |

SECOTA tests new disc grinder

October 2019 - In April 2019 the European safe standard EN 1143-1:2019 was published. The standard gives the option to additionally test with a new disc grinder. In case the product is tested with this tool, a “T2” is added to the resistance grade. The SECOTA project has already done first comparison tests with this new tool. When comparing the results from 5 different bodies the comparison showed that the current 125 mm disc cutter is at medium 3,1 times slower than the new “T2” disc cutter with 125 mm disc. This proves for the first time that the new “T2” option gives a security benefit for the user of the safe. The test was done on a metal construction. The effect on other safe constructions may be different. |

Third meeting of steering committee

| September 2019 - On 5 September 2019 the SECOTA steering committee had their third meeting. After discussing the results of the SECOTA comparison test, where eight of the burglary tools for attacking safes were assessed, the participants from seven different countries decided to focus on the three most important tools before performing the next tests. It was decided to especially evaluate the data of the 125 mm disc grinder, the oxyacetylene torch and the drilling machine. The next SECOTA steering committee meeting will then specifically have these tools on the agenda. |

SECOTA presentation in Haarlem

| June 2019 - On 24 May 2019 the SECOTA secretary Falko Adomat presented the results of the first SECOTA comparison test at the eurosafe general assembly in Haarlem (Netherlands). The 30-minute presentation was well received and included the main testing results in an anonymised form. Tests which were shown during the speech included attacks with disc cutters, acetylene torches, drilling machines and thermal lances. Eurosafe is the umbrella organisation of the national European secure storage unit associations and was founded in Paris in 1988. |

Meeting of the SECOTA steering committee

Results of first SECOTA tests have been clustered

May 2019 - From March to May 2019 six European bodies participated in the first SECOTA comparison test. The results have now been clustered in a twelve page report. As a next step the "SECOTA steering committee" will evaluate the data and discuss the results in their next meeting. |

Launch of SECOTA Comparison Test

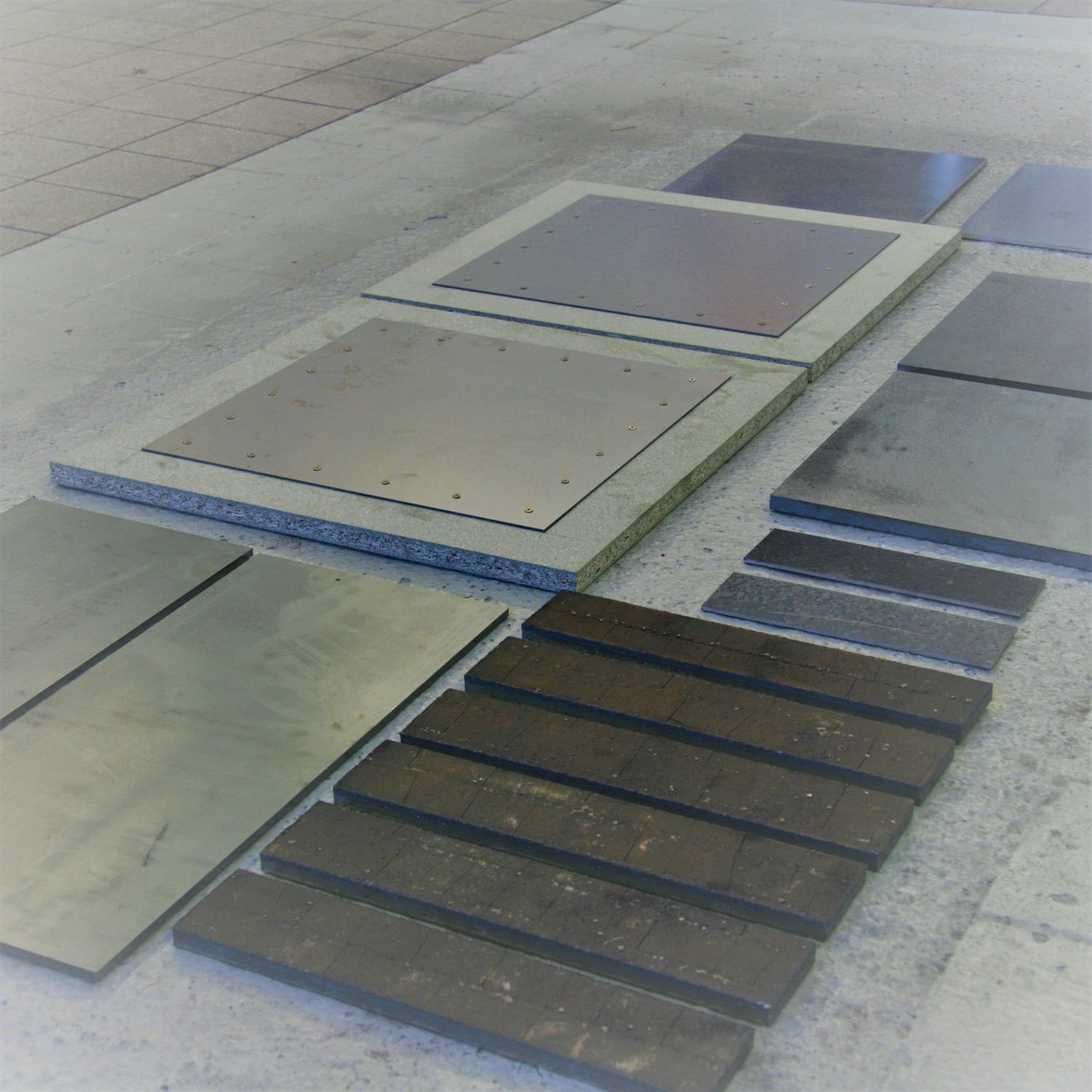

SECOTA – Test specimens completed for first comparison test

| February 2019 - A total of 126 specimens were produced for the SECOTA project. The test specimens range from simple sheets of metal to highstrength armour plates and sandwich structures. In March 2019, 16 specimens will be sent to each of the bodies that have agreed to cooperate. The first results of the comparative tests should be available in May 2019. The picture shows the test specimens, which shall be attacked by one laboratory with several specified attack tools according to the standard. |